The principle behind the operation of a Langmuir Blodgett (LB) trough is to record the compression isotherm for an amphiphile film (monolayer) residing at the air(gas)/water interface. To achieve this a small, known quantity of the material of interest is dissolved completely in a volatile solvent (such as chloroform) and is then carefully applied via syringe onto a clean water surface. Following evaporation of the solvent, the film compression starts by movement of the mobile barriers. This results in an increase in surface pressure which is recorded as a function of the area per molecule in the film.

|

|

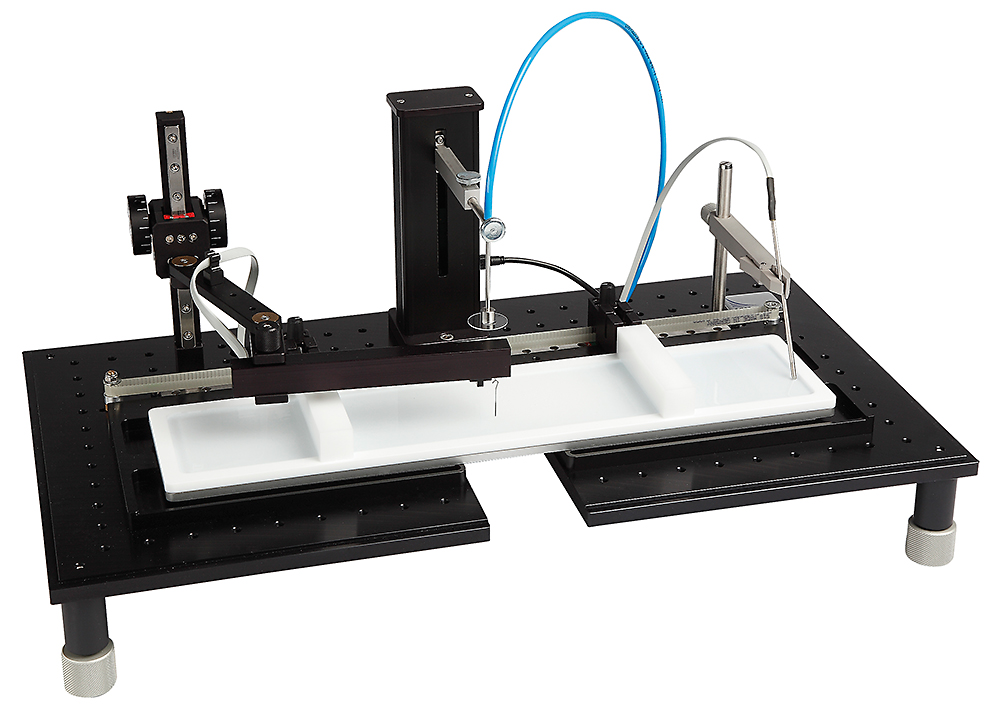

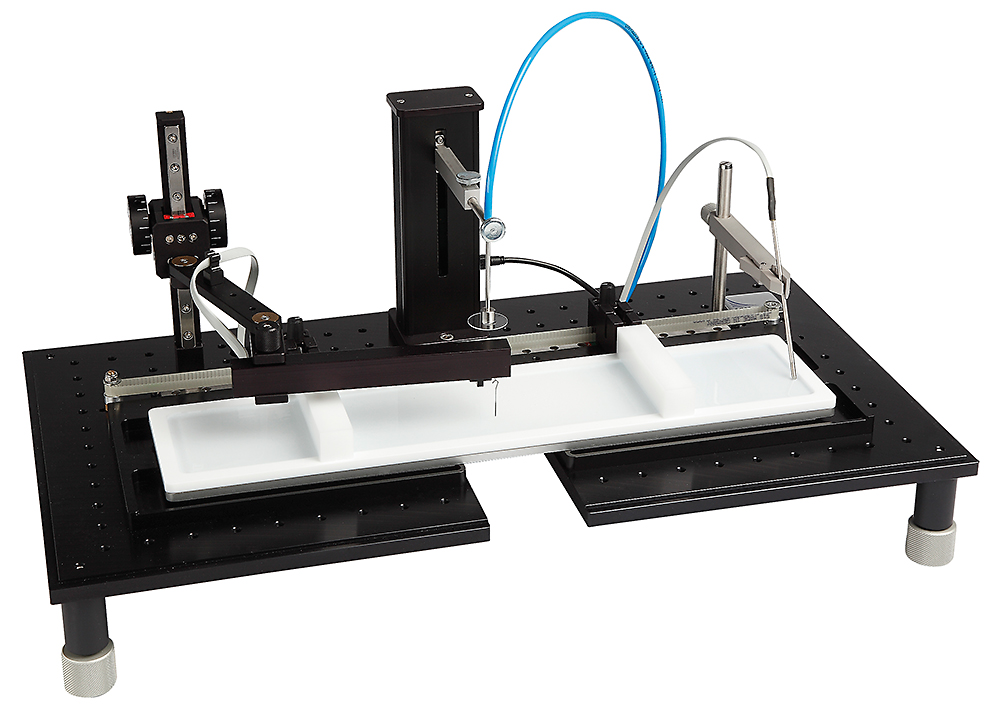

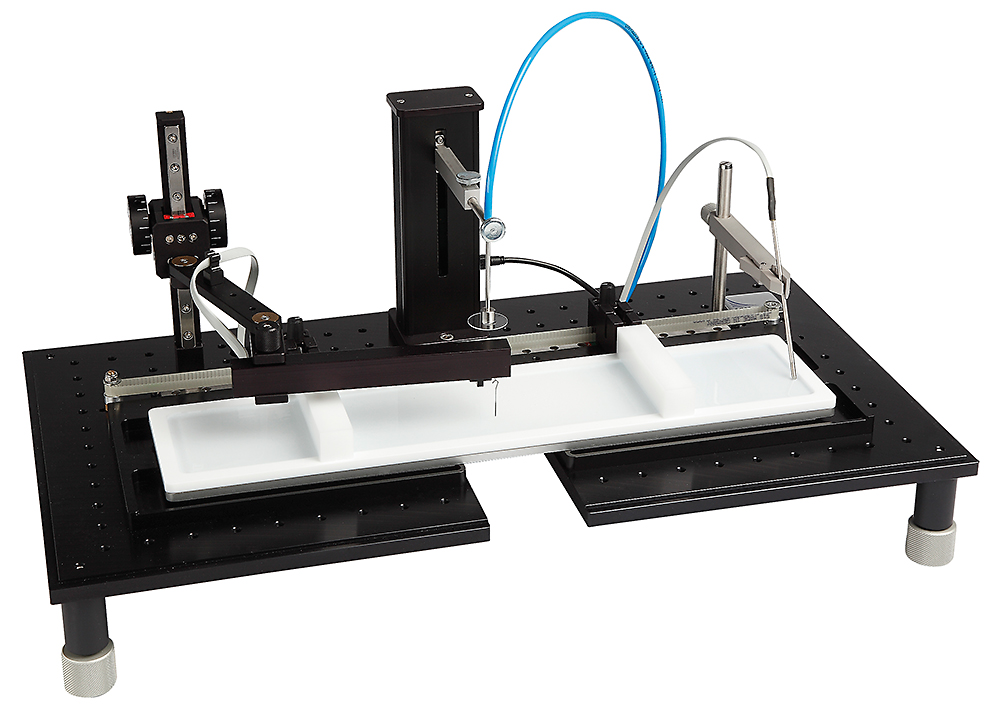

Fig: Kibron Langmuir-Blodgett equipment and the compression isotherm

The core technology in our Langmuir Blodgett (LB) Troughs is the proprietary Kibron sensor (0.2 microgram resolution), which allows detection of surface pressure and measurement of compression isotherms with a very high sensitivity, (0,01 mN/m) which yields excellent reproducibility. The high sensitivity and small diameter rod used to measure surface pressure allows very small sub-phase volumes to be used for both surface tension and pressure measurements; accordingly, LB coatings can be deposited on small surface area substrates. Owing to the high resolution and negligible noise of the Kibron microbalance, all changes in the isotherm are evident in real-time and require no signal averaging.

Flexible accessories for the Langmuir-Blodgett Trough expand the range of experimental possibilities; dip coaters allowing thin film (monolayer) deposition on varying surfaces, Surface Potentiometer for surface potential measurements and troughs with optical windows to combine simultaneous microscopy measurements are available.

Removable and interchangeable Langmuir-Blodgett Trough tops either from PTFE or metal alloy allow the user to easily clean the trough between experiments. Systems can be easily configured according to the parameters for the monolayer film being studied; the inexpensive nature of the Langmuir Blodgett trough tops enables different researchers to consider having their own.

|

|

|

Fig: Langmuir-Blodgett Trough, Surface Potential Trough and Microsopy Trough

Stand alone, manual or software controlled Dip coaters are available for use with all Kibron Langmuir troughs and can accommodate a wide range of substrate sizes for either Langmuir Blodgett (LB) deposition (vertical) or Langmuir Schaefer (LS) deposition (horizontal). The interchangeable trough top system allows the correct size trough & dipping well to be easily positioned as & when needed. Simple or Complex dipping profiles can easily be set up for multi-layer deposition as required.

A temperature control plate and a complete enclosure box for the Langmuir Blodgett trough (which may be purged with a gas) allow sensitive experiments to be set up. All functions are comfortably controlled and data captured through our new FilmWare Software which is simple to use yet powerful in capability with add-ons for specialist research areas like interfacial rheology and the same Langmuir Blodgett Trough.